10. June 2010

New Pump Range - GPD Series Pumps

Category News

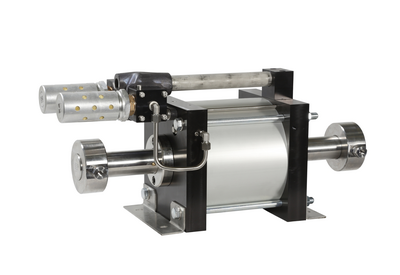

The GPD Series is the first pump series with an air drive piston of a diameter of 10“. A wide range of different pressure ratios guarantees the best solution for your specific application. To achieve a high working pressure from a relatively low air drive pressure double air drive section versions are available for the ratios 1:30, 1:60, 1:120, 1:180 and 1:260.

The GPD pumps have been specifically designed to give a high discharge flow for fast fill at a relatively high discharge pressure.

The new GPD Series Pumps are used in a wide range of applications primarily in Oil and Gas, Refinery, Petrochemical, Steel and Civil Engineering Industries. Applications exist for pressure testing large diameter pipelines, large hose reels and umbilicals, wellhead control valves, operating Subsea valves, and the charging of hydraulic accumulators. In addition they are used in Chemical Injection applications for high flow of chemicals such as methanol, glycol and other related chemicals.

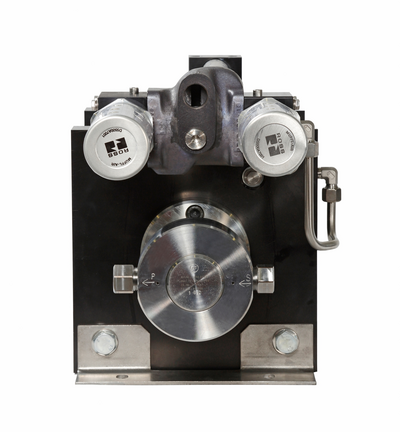

Pumps of the GPD Series that are marked with an EX sign and are supplied with a declaration of conformity as defined in 94/9/EC may be used in areas subject to explosion hazards. They are in conformity to Group II Category 2G Explosion group IIB constructive safety.

They will handle hydraulic oil, water or chemicals. The high grade of materials from which the pumps are constructed ensures corrosion issues are kept to a minimum.

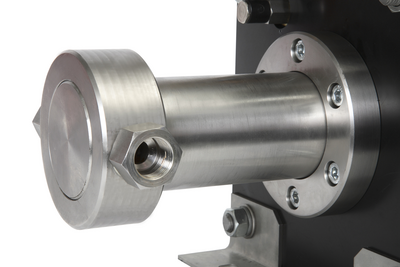

The design of the GPD pumps was primarily focussed on the ease of maintenance and its safe operation. The inlet and outlet check valves are a cartridge style which allows simple, easy exchange and replacement where necessary. In addition, by simply removing the tension ring, the complete high pressure section can be removed from the pump. This allows the checking and easy exchange of the high pressure seals with minimum effort when required.

Full separation of the air drive section and the hydraulic section is guaranteed because of a distance piece design between these areas thus ensuring no cross contamination can take place.

For further information please click on the following range:

The latest five articles

06. May 2024

Project presentation: h2-well-compact

Hydrogen innovation from Thuringia: presentation of an innovative mobile storage and compression solution for decentralized applications.

25. September 2023

Download of product drawings and 3D step files available

With the new download function, the product drawings and 3D step files are now available for download in our ePortal for a large number of our products.

08. November 2022

Out now! Maximator Liquified Gas Pumps

The pressure remains in focus - not the phase. Discover now our new pump series for liquid gases.

07. June 2022

Full control at every moment

In this "Best Practice Double Block and Bleed Needle Valves" you will learn more about the background and applications of the Maximator double block and bleed valves.

22. March 2022

X-Tower - the most flexible gas filling system

The Maximator X-TOWER is a modular Gas Compression System, specifically designed for Hydrogen compression up to 900 bar with scalable volume flow. The X-TOWER is designed for integration in existing systems and is covering nearly all requirement for efficient gas compression. So it offers more flexibility than ever before!