The Maximator HULC series is a modular gas compression system, specifically designed for hydrogen compression up to 1,050 bar with scaleable volume flow. In addition to innovative technologies such as the new Nitrogen Flow Purge purging process or our Flex Drive efficiency booster, the HULC series is particularly impressive due to its modularity in a wide range of hydrogen compression applications.

The sustainable and secure supply of clean energy to our society is one of the greatestchallenges of our time. Hydrogen combines energy security, climate neutrality and, as anenergy carrier, has extraordinary potential to make a significant contribution to the energy transition.

If hydrogen is produced by electrolysis at low pressure (e.g. approx. 8 - 40 bar) it must be compressed to the highest possible pressure level for storage. For example, long-term storage tanks (home power solutions) are filled or forklift trucks, drones, pilot vehicles such as buses and cars are supplied with hydrogen. However, high-pressure hydrogen is also required for recovery applications, laboratory applications and other power-to-gas applications.

At Maximator, we have been specialising in high-pressure technology for hydrogen applications for more than 20 years. As a manufacturer of valves, fittings and gas boosters, we know exactly how they seamlessly work together in an optimal system - trust our hydrogen high-pressure expertise.

The Maximator Hulc series is a pneumatically operated, highly modular hydrogen compressor system. In addition to innovative technologies such as the new exchange concept, the Nitrogen Flow Purge process and our FlexDrive technology for efficiency-boosting, the Hulc series is particularly impressive due to its modularity. Depending on the application, the Hulc can be configured precisely to the respective requirements.

An important contribution to the sustainability of technical solutions is the implementation of energy-efficient measures.With this in mind and supported by market feedback and customer surveys, we have developed various product-related optimizations. The unique and patented Flex-Drive technology for our pneumatically operated gas compressors with two air drive sections is one of these optimizations to achieve ecologically efficiency-enhancing goals.

With Flex Drive technology, we offer our customers a unique opportunity to get the most out of their high-pressure technology in terms of efficiency. The technology allows the two air drive parts to be pressurized independently of each other and therefore only one of the two compressed air drives to be used when the power requirement is low (principle of the area ratio drive section vs. high-pressure section).

This is particularly advantageous when filling large storage tanks over long periods of time or in the process of initially low-pressure relevant volume flows. When a certain pressure level (Flex pressure) is reached and one air drive section is no longer sufficient to supply a constant volume flow or pressure, the second air drive automatically switches on.

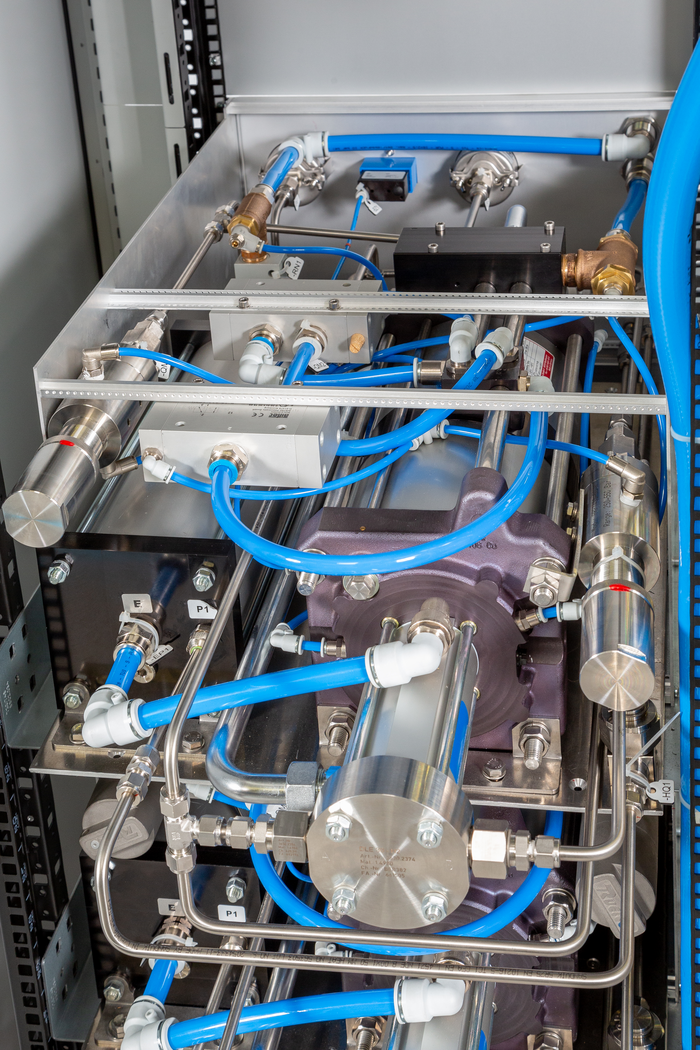

The maintenance concept of the Hulc-Solution impresses with its user-friendliness and minimal downtimes. Thanks to the modular concept of the respective compressor slide-in modules, all that is required is to disconnect the supply connections. The module to be serviced can then be pulled out of the drawer and a new module inserted. After connecting the supply lines and a leakage test, your system is ready for operation again - all within approx. 30 minutes.

Simply send the module to be serviced to us. Your module will be professionally dismantled, checked and repaired. You can obtain replacement modules from our stock.

The modules can be replaced by our service experts or your own trained specialist personnel. Training and practical instruction is provided by our TÜV-certified trainers at our Maximator Academy - please contact us for more information.

Maintenance is recommended after approx. one million cycles or one year of operation (corresponds to an average of 1.2 tons of compressed hydrogen).

A standard configuration up to 1,050 bar consists of one control module (MASTER-module) and up to four gas booster modules (X-modules) - first stage module up to 90 bar, second stage module up to 300 bar, the third stage module up to 600 bar and the final stage module up to 1,050 bar. This configuration will provide a gas outlet flow of 2,5 kg Hydrogen per hour (average). For higher outlet capacities more modules can be connected easily.

This complete series is installed in 19“ rack frame with front panel mounting and front connection for easy installation, exchange and access. This system can be easy installed and combined.

For all applications the MASTER module is mandatory and is handling safety and functional features for maximum four X-modules. The X-modules can be combined and connected depending on the application.

Purge function on the high-pressure side: inertisation of the high-pressure sections with nitrogen

Designed as an easy changeable 19" rack. For maintenance friendly access all connections are installed in the front of the panel. This design reduces the down-time for maintenance, as the complete module can be changed easily in short time.

Is required to operate up to three modules and is handling the gas supply with the pressure outlet and pressure bleeding requirements.

The air supply line will be separated for each individual module, protected with an internal safety relief valve and will be switched off if the gas supply pressure will drop below the settings.

Is containing the heart of the system - the air driven gas booster and control gauges to check the gas supply and working pressure.

A modular gas compressor specially developed for compressing hydrogen | Language: English | Release: 03/2025

Download

Do you have any questions about the HULC series? Please feel free to contact me!

+49 3631 9533 5147