29. September 2017

Maximator and University of Zurich develop HPL6 high-pressure homogenizer

Kategorie News

High-pressure cell lysis including four-zone cooling

The system has been designed to the latest standards for laboratory operations and specially optimized with regard to temperature control and cleaning. Now that the prototype has been thoroughly tested by UZH's Biochemistry Department and achieved positive results throughout, Maximator is taking on production and global sales of the HPL6 high-pressure cell lysis unit.

High-pressure systems for physical cell lysis are used in medical technology, biotechnology, chemistry, biology and the pharmaceutical industry, particularly in research, to "break" cell walls. It is usually not crucial to adhere exactly to a specific low temperature in this process; that is why only the sample vessel in the final step of the process is cooled in most of the commercially available systems.

This type of cooling, however, was not sufficient for a project of UZH's Biochemistry Department, the aim of which was to capture and analyze intact cell membranes. On this subject, Prof. Raimund Dutzler, from the University of Zurich, says: "In order to preserve the cell membranes undamaged, the temperature range in our case needs to be below 8 °C throughout. Commercially available systems were unable to achieve this. What we needed, therefore, was a new device that keeps the temperature constantly cool across every individual step of the process." At the same time, the device was to be easier to clean than currently available systems.

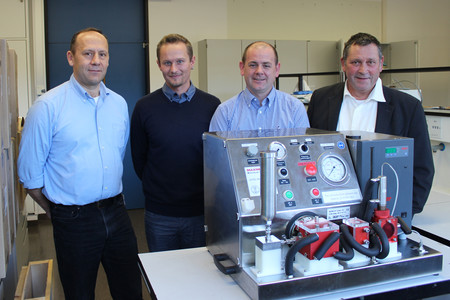

The HPL6 high-pressure system is delivered to the University of Zurich. From left to right:

Prof. Raimund Dutzler, Sascha Weidner (both from the Biochemistry Department, University of Zurich), René Himmelstein (Maximator GmbH Deutschland), Peter Brülhart (Maximator Schweiz AG). Picture: Maximator GmbH

UZH designed a prototype according to its own high requirements, which Maximator GmbH, one of the leading suppliers of systems and components for the high-pressure technology sector, transformed into a reproducible system and is now bringing to market. The HPL6 (High Pressure Lyser, 60,000 psi) achieved consistently positive results in UZH's tests, setting new performance standards.

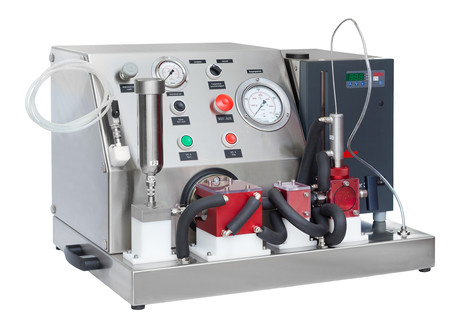

Four-zone cooling for even temperature

The HPL 6 has a four-zone cooling system, which means that the temperature is constantly kept at > 2° C over the entire process, i.e. also in those areas in which heat is generated.

The cooling zones are located on the high-pressure pump head (pump cooling), on the piping between pump and needle valve (T-piece cooling), on the lysis nozzle (nozzle cooling) and on the sample vessel containing the finished product (outlet cooling).

Simple handling, problem-free cleaning

It was very important to Maximator and UZH's Biochemistry Department that the system should be suitable for everyday use. By using high-quality quick-lock couplings made of stainless steel, switching between sample vessel and flushing head is carried out quickly. The cleaning effort is significantly reduced - a huge advantage over comparable systems. Whereas cleaning and disinfection took around 15 to 20 minutes in comparable systems, they take no more than 5 minutes with Maximator's HPL6.

A further plus point is that simple handling and fast cleaning speed up the entire process flow, thereby also contributing to cost reduction.

Convincing benchmark data confirm best performance for high-pressure cell lysis

Maximator's quiet and low-maintenance HPL6 can already be operated with a sample volume upwards of 20 ml. The dead volume is significantly minimized, at less than 6 ml.

Apart from the extremely high cooling capacity of approx. 2 °C for even the most difficult use cases, the system impresses by virtue of good flow rates at very high pressures (maximum pressure: 4,200 bar / 60,000 psi). The flow rate of E.coli, for example, is 120 - 330 ml/min at 1,400 bar / 20,000 psi while, for yeast, it is 80 - 150 ml/min at 3,200 bar / 45,000 psi.

The measured data of the powerful HPL6 confirm that Maximator has achieved its goal, targeted at the very beginning of the development, of becoming "best in class" in this area. René Himmelstein, Vice-President of Sales and Marketing at Maximator, adds: "HPL6 has been developed with users for users, which is having a positive impact in physical cell lysis practice. Through this development, our company is also opening up a new area of application for high-pressure technology, which is being marketed exclusively by Maximator. Apart from this biochemical use for organic material, the system may also be of interest in respect of other analysis tasks, e.g. in testing laboratories of the food industry or waste water technology."

Further information

About the University of Zurich and the Biochemistry Department

The University of Zurich (UZH), founded in 1833, is Switzerland's largest university, with over 25,000 students, and nowadays is one of the best universities in the German-speaking world. As a member of the "League of European Research Universities" (LERU), UZH belongs to Europe's leading research institutions. To date, the Nobel Prize has been conferred on twelve UZH scholars, including Albert Einstein and Conrad Röntgen.

Research at UZH's Biochemistry Department focuses on the functional investigation of proteins, using biophysical, biochemical and structural methods. Currently, the department houses six research groups. The department's mission is to be a leader in protein technology and structural biology and to conduct international-level cutting-edge research.

About MAXIMATOR GmbH

Maximator GmbH is one of the leading suppliers in the high-pressure and test technology, hydraulics and pneumatics sector. Its employees develop, design, manufacture and distribute international products that are used in industrial systems across the world. The company manufactures, among other things, systems for gas and water-assisted moulding applications, gas dosing stations, high-pressure pulse test systems, burst pressure test stands, leak test systems, autofrettage machines as well as high-pressure pumps and high-pressure gas boosters, hydraulic units and booster stations, valves, fittings and tubings. Maximator's long-standing experience in the project business for test and production systems makes it a valuable partner for the automotive industry, general mechanical engineering, the chemical and petrochemical industries as well as the oil and gas industry.

Die fünf neuesten Artikel

12. Februar 2026

Maximator eröffnet neuen Reinraum in Nordhausen: Ausbau der Fertigungskompetenzen für Kundenprojekte in der Halbleiterindustrie

Maximator hat einen neuen Reinraum eingerichtet, um Fertigungsprozesse noch präziser und sauberer durchführen zu können. Für den neuen Produktionsbereich investiert das Unternehmen rund 250.000 Euro und schafft damit eine wichtige Grundlage für weiteres Wachstum in anspruchsvollen Branchen wie Halbleiter-, Medizin-, Lebensmittel-, Pharma- und Biotechnologie. Bei der Planung und Umsetzung wurde Maximator vom Industrietechnik-Spezialisten item unterstützt.

24. Oktober 2025

Tag der Ausbildung bei Maximator – Entdecke deine Zukunft!

Bist du bereit, den Grundstein für deine berufliche Zukunft zu legen? Dann verpasse nicht den Tag der Ausbildung bei Maximator, der am 15. November 2025 von 10 bis 14 Uhr stattfindet! Extra für Schulen gibt es einen exklusiven Blick hinter die Kulissen am 14. November 2025.

01. Oktober 2025

Save the Date: Hydrogen Technology Expo Europe 2025 und SK Get Together

Maximator stellt das Wasserstoff Portfolio auf der Hydrogen Technology Expo Europe 2025 vor und hat ein ganz besonderes Highlight - das SK Get Together! Sie sind herzlich eingeladen bei ein paar kühlen Getränken über die neuen Innovationen in der Welt des Wasserstoffes zu diskutieren!

31. März 2025

Wegweisender Durchbruch in der Hochdruckventiltechnik

Maximator GmbH bietet mit der neuen Ventilserie ValvolutionX Nennweiten bis 1Zoll bei zugleich 50% kompakterer und 75% leichterer Bauweise

24. März 2025

Neues Kapitel, neue Möglichkeiten - Gründung Maximator Polen

Maximator startet mit der Gründung von Maximator Polen ein neues Kapitel.