Gas and Water Assisted Moulding

What is Assisted Injection Moulding?

Assisted Injection Moulding (AIM) is part of a family of technologies that are operated with plastics processing methods to improve product quality and significantly reduce cost.

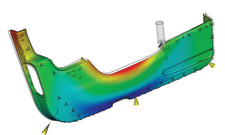

The technologies include the injection of gas or water at high pressure into plastic in an injection mould. This cores out sections of the part, leaving hollow areas. These reduce part weight and can provide much better distribution of packing pressure and eliminate sink marks. Gas can also be applied to the surface of a plastic part to replace moulding machine packing pressure with a uniform gas packing pressure, eliminating sink marks and reducing clamping force and often leading to lower part weight and cycle time.

The technologies include the injection of gas or water at high pressure into plastic in an injection mould. This cores out sections of the part, leaving hollow areas. These reduce part weight and can provide much better distribution of packing pressure and eliminate sink marks. Gas can also be applied to the surface of a plastic part to replace moulding machine packing pressure with a uniform gas packing pressure, eliminating sink marks and reducing clamping force and often leading to lower part weight and cycle time.

Other processes involve creating foam in plastic resins to reduce density, or thermal cycling of moulds to eliminate weld lines. The technologies can often be combined to achieve additional benefits, depending upon the application.

Service for your Gas- and Water Injection Systems

Our team of more than 50 specialists is ready to provide support with technical and engineering expertise at 20 locations around the globe, in order to assist with everything involved in your system - from the stage of operational startup, through operator training, to maintenance.

Our team of more than 50 specialists is ready to provide support with technical and engineering expertise at 20 locations around the globe, in order to assist with everything involved in your system - from the stage of operational startup, through operator training, to maintenance.

In addition, we supply your gas and water assisted systems at all times with original spare parts.

Aligned to transparency, we demonstrate to you the functioning method of the technologies in product instructions, so that you economize on time and costs right from the beginning.

As a result of safe and competent handling in operating and maintenance work, you contribute to a longer service life of all components and prevent unnecessary shutdowns - your investment is thus ensured in the long-term.

As a result of safe and competent handling in operating and maintenance work, you contribute to a longer service life of all components and prevent unnecessary shutdowns - your investment is thus ensured in the long-term.

Maximator service and maintenance agreements guarantee the regular maintenance and repair of your system.

We take the load off in your day-to-day business, where we make sure that the inspection schedules and continuous maintenance are planned and implemented, so that the performance capability of your machine remains at the highest level.

DESIGN CONSULTANCY & TOOLING SERVICE

Design, Consultancy and Tooling Projects experts are available worldwide to advise how gas assisted moulding can benefit your product and company - from concept to production. CAE plastic and gas flow analyses are provided when appropriate.

Design, Consultancy and Tooling Projects experts are available worldwide to advise how gas assisted moulding can benefit your product and company - from concept to production. CAE plastic and gas flow analyses are provided when appropriate.

Mould Trials

Mould trials may be undertaken at our global facilities or supervised by our technicians at a moulder’s factory.

Comprehensive training for customers including:

- Factory technicians – in the operation of all Maximator equipment and processes

- Maintenance engineers – in the servicing and maintenance of Maximator equipment

- Design engineers - in the design of AIM products to take full advantage of the potential economic and technical benefits

- Sales people – in the advantages and benefits of AIM as well as the scope for design flexibility, with a view to increasing sales with new product applications.

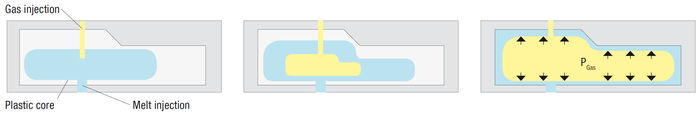

The short shot process

Injection phase

|

Gas injection phase

|

Gas hold-pressure phase

|

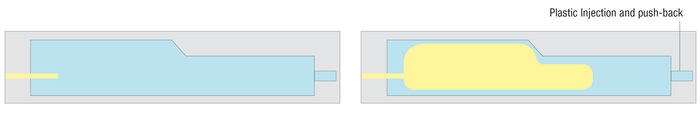

The full shot process

Push-back process

- The cavity is completely filled with melt - at the flow path end the gas injection begins.

- The molten core is pushed back into the barrel of the molding machine and the screw is withdrawn.

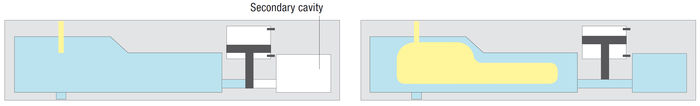

Overspill process

- The cavity is completely filled with melt. A secondary cavity is connected to the main cavity by a valve gate.

- The surplus mass is displaced into the secondary cavity by the gas pressure.

Systems technology of gas and water assisted molding technology

For the application of gas and water assisted injection technology, as well as the injection molding machine, basically two additional functions are to be applied: Pressure generation and pressure control.

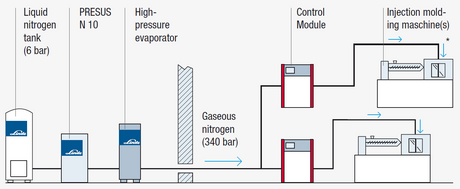

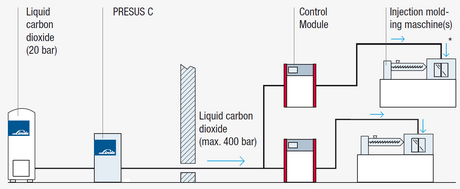

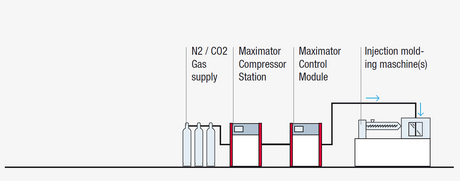

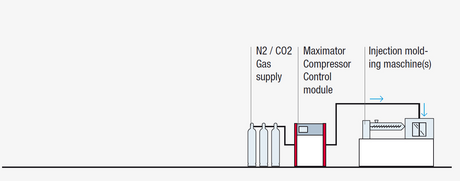

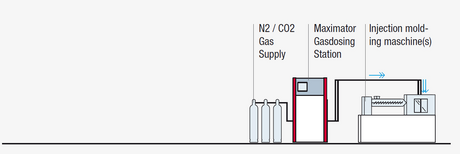

In the area of gas assisted molding technology, two different types of gas pressure generation are differentiated. On the one hand, discontinuous gas pressure generation which is mainly employed for the GIT process in case of individual machines and, on the other hand, continuous gas pressure generation which is employed for the centralized supply of several injection molding machines. The gas pressure regulation is applied individually with pressure-control modules at every injection molding machine. The pressure-control module decreases the supplied system pressure to the necessary gas pressure. Communication with the injection molding machine is realized by means of an electrical control. Maximator offers compressor stations and control modules, as well as combined compressor control modules, for discontinuous and continuous gas pressure generation.

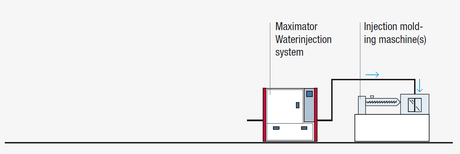

In the area of water assisted molding technology of the MAXIMATOR WID system, both the pressure generation and the pressure control are applied in one system. The following schematics indicate the basic structure of the systems technology.

Gas assisted molding with liquid gas supply

Supply with liquid nitrogen

Supply with liquid carbon dioxide

Gas assisted molding with gas bottle supply

Compressor Station and Control Module

Compressor- Control Module

Water assisted molding

Gasdosing Technology

* Courtesy of Linde AG