High Pressure Pumps

The MAXIMATOR air drive concept provides a number of benefits to you:

- Pressure regulation via manual pressure control units or pneumatically triggered valves

- Pressurised air drives, i.e. the pumps are particularly suitable for application in explosion-proof areas

- Stalling of the pump upon reaching the pre-selected ultimate pressure

- Substitution of leakages by automatic additional delivery of liquid from the pump

- No energy consumption during long pressure holding periods

- No heat loss during the pressure holding phase

- Easy installation and problem-free operation of the units. Only connections to air supply as well as suction and pressure lines are required

- Operationally reliable, easy-to-install and low-maintenance units, quiet in operation

MAXIMATOR provides competent consultancy, engineering design and supply of complete systems to optimally and economically solve your testing tasks and offers you extensive Services.

MAXIMATOR Pumps are available in 5 sizes: M, S, G, GX, DPD. The sizes vary according to their suitability for different pumping media, wide ranging flow rates and their maximum allowable operating pressures. MAXIMATOR provides the best-suited fluid pump for each application.

Installation and operating manual Air driven high pressure pumps_EN

M, M...D, M...-C, MO, MO...D, M...-2, M...-3, M...-ECO, M...- HL, S, S...D, S...-SS, G, G...D, G...-C, G...-2, MSF, GSF, GPD, GPD...-2, GX, DPD Language: EnglishMaximator High Pressure Pumps

3999.0467, Language: English, Release: 02/2024Further general suggestions to operate the Air Driven Liquid Pumps properly

Assembly positions

MAXIMATOR pumps can, in principle, be installed in any position, but a maximum service life of the seals is achieved in a vertical one.

Port sizes Important!

Please observe that only screws and tubing are fitted that are suitable for the pressure range of the pump. To ensure an optimum operation (pressure and flow) of the pumps, the port sizes of the pumps shall not be reduced.

Drive air connection and initial operation

The air drive connection is located at the spool valve housing. A second air drive connection as unregulated pilot port on S...D and G(SF) series that has to be connected too, not only provides better pressure control but is also the ideal place to install control instrumentation because of its small size. In any event a compressed air filter and water separator has to be fitted to the pump. Filters with water separator, pressure regulator, control pressure gauge and shut-off valve are optionally available under ”Air control unit C....“, depending on the pump line.

No air lubricator is required since the pump received Barium grease treatment. Has a lubricator been used once, it is strongly recommended to continue. If there is only very dry air available, an air lubricator is needed.

Operating temperatures for MAXIMATOR pumps

are in general between –20°C to +80°C (standard). The pumps with –VE seal version can be operated up to max. +60°C, at short term up to +80° would be acceptable. For outdoor service at temperatures of 0°C and below, special versions are available on request.

Recommended hydraulic oils

Proper operation and efficiency of the pumps is mainly depending on the quality of the used hydaulic liquid. We recommend hydraulic oils with a viscosity between 46 – 68 cst, i. e. Manufacturer Hydraulic oil to DIN 51524 T2; DIN 51519; ISO VG 46

| ARAL | VITAM GF 46 |

| BP | ENERGOL HLP 46 |

| ESSO | NUTO H 46 |

| SHELL | TELLUS Oil 46 |

|

|

HYDROL DO 46 |

|

|

HYDROL HV 46 |

| DEA | ASTRON HLP 46 |

Recommended quality of drive air

The drive air should have a quality class of 3 to 4 (solids/water/oil) according to the recommendation no. 611/1984 by PNEUROP (European Committee of Manufacturers of boosters, vacuum pumps and air driven tools).

- Solids: maximum particle size 5µ, maximum particle concentration 5 mg/m3

- Dew point: + 10° = water content of 9.4 g/m3 to + 2°C = water content of 5.6 g/m3

- Oil content: 1.0 to 5 mg/m3

Please note that by using humid air of high humidity in continuous operation the problem of icing could occur. We suggest to install a water seperator and a dryer in the drive air line. If the drive air is too dry and has got a dew point lower than - 40°C, we suggest to use an oiler. By observing this drive air quality, an optimum life time of the seals and packings will be achieved.

MAXIMATOR pumps are suitable for liquid applications. To select and order a hydraulic pump that is suitable the best for your applications, the following parameters have to be observed:

1. Liquid to be handled

The type of liquid is essential to select a MAXIMATOR pump hence the wetted material of construction and compound of the seals are determined by the specific fluid. MAXIMATOR pumps are available for several services. The two most important we are offering standard pumps are for oil or water use, see also ordering codes.

2. Available Air Drive pressure

MAXIMATOR pumps are designed for an air drive pressure of pL = 1 to 10 bar (14,5 to 145 psi) maximum.

3. Required hydraulic outlet pressure and flow capacity

The outlet pressures given in the technical pump tables are based upon a maximum air drive pressure of pL = 10 bar. The real oulet pressure in your specific case is determined by air drive pressure multiplied by pressure ratio, pL * i. The indicated flow capacities Qmax is the maximum value which can be reached at an outlet pressure of 0 bar and an air drive of pL = 6 bar. The real flow capacities at a specified outlet pressure are listed in the flow charts, page 20 to 23.

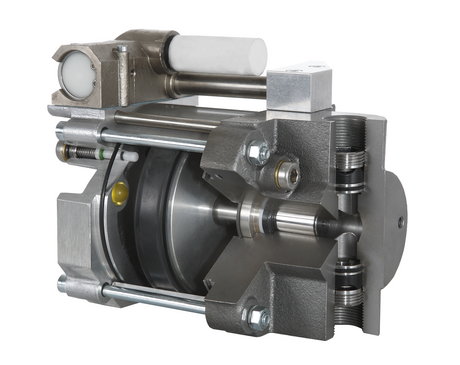

MAXIMATOR high efficiency pumps are ideal for a broad variety of oil, water and chemical applications. MAXIMATOR pumps are air driven at a drive air pressure of 1 to 10 bar (14,5 to 145 psi). Basically the principle of operation is similar to a reciprocating amplifier where control of the piston at the end position is regulated by a pilot operated 4/2 way valve.

MAXIMATOR pumps feature a large air piston joint to a smaller diameter plunger. The pressure ratio is the difference of these two areas and is the method of determing maximum outlet pressure. Higher pressures are obtained by using higher pressure ratios. MAXIMATOR model numbers reflect the pumps’ nominal pressure ratios, while the technical data indicates exact ratios. The outlet pressure is easily to set through a simple air regulator. By multiplying the pressure ratio by the available shop air pressure, the nominal liquid pressure can be calculated.

MAXIMATOR pumps are self priming. In general it is not necessary to use an air line lubricator. The liquid to be pumped, flows into the suction chamber by the up-stroke of the drive piston. By this suction effect, the inlet check valve is opened and the outlet check valve is closed. The down-stroke generates the pressure at the liquid side. The inlet check valve is closed and the outlet check valve is opened by the generated pressure.

MAXIMATOR liquid pumps cycle automatically. When the pressure is built up the numbers of cycles slow down. The pump stops automatically when the output pressure forces are equal. The pump restarts with a slight drop in the outlet pressure or an increase in the air drive pressure. Pump performance can be effected by a number of conditions, such as freezing of muffler or pilot valves (which is caused by moisture in air lines), inadequate inlet air line sizes and dirty filters. Don’t reduce the indicated port sizes and consult

MAXIMATOR offers complete technical and service support for all MAXIMATOR pumps.

Maximator High Pressure Pumps

3999.0467, Language: English, Release: 02/2024Series MO and S

up to 1,000 bar (14,500 psi)

The rugged construction, light weight and wide range of pressure ratios make these series of pumps ideal for powering a variety of oil/hydraulic operations. They are available as single or double acting models.

Oil Service Pumps

- Lifting and Jacking – lifting tables, scissor jack lifts, beam jacking and aircraft jacking

- Hydraulic Operation – clamping devices, punches and pin presses, chucks, valve actuation

- Presses – cold isostatic presses, filter presses, hydraulic presses, hydraulic press actuation and system overload

- Tooling and Tightening – actuating cropping, crimping, cable shears and pipe bending tools, roller tensioning and torque wrenches

- Testing – tensile test machines and pressure testing

- Miscellaneous – lubrication systems

Series M and G

up to 5,500 bar (79,750 psi)

The M and G series pumps are available in single or double acting models with single, double (M and G series or triple (only M series) air drive heads and wetted materials of stainless steel, making them an excellent choice for water application.

Water or Oil Service Pumps

- Hydrostatic Testing – valves, tanks, pressure vessels, pressure switches, hoses, pipes and tubing, pressure gauges, cylinders, transducers, well casings, BOPs, gas bottles and air craft components

- Burst and Cycle fatigue testing of above components

- Calibration of pressure gauges and transducers

- Water Blasting

- Leak Testing

- Emergency shutdown systems for oil and gas wells

- Pressurization of pressure vessels for testing various components

- Operation and Control of well service and well head equipment

Series MSF, GSF and GX

up to 1,450 bar (21,025 psi)

These two series of pumps are similar to the M and G series described before. MSF and GSF pumps feature a distance piece and PTFE seals to address the specific requirements of chemical service. GX series are high flow pumps designed for rugged installations and built with environmental resistant external components. They are ideal for offshore applications with stainless steel wetted parts and corrosive resistant external components.

Pumps for Chemical and Offshore service

- Inhibitor Injection of methanol and glycol in wells

- Coolant Injection

- Aviation and Automotive Testing – brake fluid, skydrol, transmission fluid and power steering fluid

- Chemical Fluid Transfer and Pressurization

MAXIMATOR pumps for special applications

DPD series are large double acting pumps that deliver a high flow rate at high pressure up to 2,100 bar (30,450 psi).

- Test pressure generation for Mandrel Extraction Machines

- Waterjet cutting in intermittent service

Single and Two Component Injection Pumps

Grouting Pumps

Infusion Pumps

- Underground Mining Industry

- Rock and Coal Consolidation

- Tunnel and Bridge Construction

- Concrete Restauration